Fill-Rite’s fuel transfer series offers three pumps for high-flow fuel transfer; the 300, 700, and the 3200 series. This blog focuses on comparing and contrasting the 300 and the 700 series pumps. Amazon Hose & Rubber Company is a proud distributor of Fill-Rite pumps and accessories. They construct 50 years of experience into every fuel transfer pump, chemical transfer pump and meter. They deliver quality products made in the USA!

Fill-Rite’s fuel transfer series offers three pumps for high-flow fuel transfer; the 300, 700, and the 3200 series. This blog focuses on comparing and contrasting the 300 and the 700 series pumps. Amazon Hose & Rubber Company is a proud distributor of Fill-Rite pumps and accessories. They construct 50 years of experience into every fuel transfer pump, chemical transfer pump and meter. They deliver quality products made in the USA!

The 300 and the 700 series pumps have the same rotary vane technology, same inlet size (1¼”), type of threads (NPT), and warranty (2 years). Both series use thermally protected, explosion proof motors, and offer biodiesel and arctic models. Given all their similarities, what exactly are their differences, and how do you select the right series and model for your needs? To determine the best fit for your application, let’s consider five questions:

1. What type of fluid are you pumping?

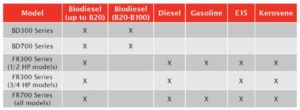

FR300 and FR700 series models are all designed to be compatible with gasoline, E15, diesel, biodiesel (up to B20), and kerosene. Pumping B20 – B100 biodiesel? Use a 300 or 700 series model with the “BD” designation at the start of the model number (i.e: “BD700V”). A 300 series model with a ½ HP motor is the best choice for stage II vapor recovery, as well as high flow pumping of gasoline. The ½ HP 300 series and 700 series pumps are also great choices for pumping gasoline because they limit the possibility of cavitation and vapor lock issues in warm weather. This handy chart will help you source the best option for the fuel you are pumping:

2. What electrical power source is available?

All 300 and 700 series models operate on AC power. 300 series pumps are switchable dual voltage 115/230 VAC, while 700 series pumps operate on 115VAC, though certain models in the 700 series that have the option of being wired for 220VAC. If a high flow rate is required, but only DC power is available, the best pump for your application is the 3200 series.

3. How fast do you want to pump?

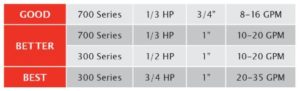

Time is money, so having the highest possible flow rate for your application is important. Accessories, like nozzles, swivels, filters, and varying lengths and diameters of hoses are important for metering and convenience, but remember accessories decrease flow rate. The chart below gives an overview of the flow rates of the 300 and 700 series pumps. The range listed varies based on the accessories used in the application.

4. How deep is the tank you are pumping from?

Suction lift plays a major role in pump selection. It refers to the distance between the pump and the top of the fuel in the tank. The 300 series averages 18′ of lift and the 700 series averages around 12′ of lift when pumping diesel, while both pump series deliver approximately 10′ of lift when pumping gasoline. It is also important to note the altitude at which the pump is operated will reduce these ratings, with a basic rule of thumb being every 1,000 ft. increase in elevation decreases a pump’s suction lift by 1′.

5. What type of accessories are included with the pump?

As noted before, accessories, like nozzles, hoses, meters, filters, and swivels, all have an impact on overall system performance because they create restrictions and back pressure. When choosing accessories, keep in mind manual nozzles typically have less restriction than automatic nozzles, and shorter, larger diameter hoses have higher flow rates than longer and smaller diameter hoses. If you add or change accessories it is important to remember the outlet size of the pump. The 700 series comes with either a ¾” or 1″ outlet, while the 300 series comes with only the 1″ outlet.

Regardless of your pump, meter and dispenser requirements, contact an Amazon Hose & Rubber Company representative at (800) 506-5514 or visit our website at www.AmazonHose.com.